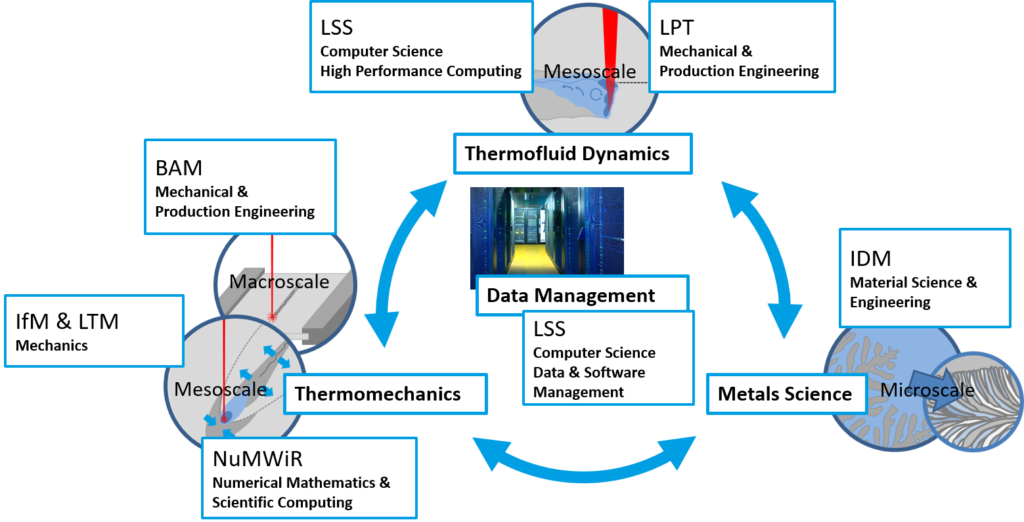

Participating institutes and disciplines

The research unit is composed of scientists who contribute their expertise to the research project in various fields: Mechanical Engineering, Mechanics, Production Engineering, Materials Science, Numerical Mathematics and Computer Science. The competences of the sub-project teams involved are complementary, so that their interaction offers a high innovation potential.

- Bundesanstalt für Materialforschung und –prüfung (BAM) – Mechanical and Production Engineering

- Institute of Photonic Technologies (LPT), Friedrich-Alexander-Universität Erlangen – Mechanical and Production Engineering

- Chair of Computer Science 10 – System Simulation (LSS), Friedrich-Alexander-Universität Erlangen-Nürnberg – Computer Science, Data- and Software Management

- Institute of Mechanics (IfM), Universität Duisburg-Essen – Mechanics

- Chair of Numerical Mathematics and Scientific Computing (NuMWiR), University of Cologne – Numerical Mathematics and Scientific Computing

- Institute for Digital Materials Research (IDM), Hochschule Karlsruhe – Material Science and Engineering

- Chair of Applied Mechanics (LTM), Technische Universität Kaiserslautern – Mechanics

Even the technological foundations of the research project in materials science require a cross-scale understanding of the physics and the laser beam welding process, so that scientists from different engineering disciplines have to combine their expertise.

Numerical mathematics is involved to develop and analyze modern cross-scale finite element models. Computer science contributes the expertise to realize these methods efficiently and sustainably on modern supercomputers. Models of this complexity can only be implemented with maximum computing power. In cutting-edge international research in simulation technology it is therefore necessary to extend and combine traditional topics from mathematics and computer science in such a way that they can represent the complexity of realistic physical models and processes based on them. Of course, the algorithmic models must be developed in close cooperation with the application disciplines. The implementation of such simulation models on supercomputers requires the interaction of all these competences.

Value added through interdisciplinary collaboration

The cooperation of the different disciplines and simulative approaches within the research unit results in an enormous added value compared to the isolated consideration of individual effects or mechanisms within the framework of individual projects. On the one hand, experimental methods can only contribute to a limited extent to an understanding on solidification crack formation due to the high process temperatures and low accessibility. On the other hand, simulative investigations from only one point of view always suffer from having to neglect the complex interactions. Therefore, transferability and quantification are impossible. Only a holistic interdisciplinary approach to solidification crack formation as a special case of thermomechanical or microstructural processes during solidification in laser beam welding can provide a comprehensive transferable and quantifiable understanding of the process. The cross-scale modeling of multiply coupled physical phenomena leads to an enormous complexity of the software and at the same time requires a computing power that currently only massively parallel supercomputers can provide. This requires an interdisciplinary computational engineering approach.